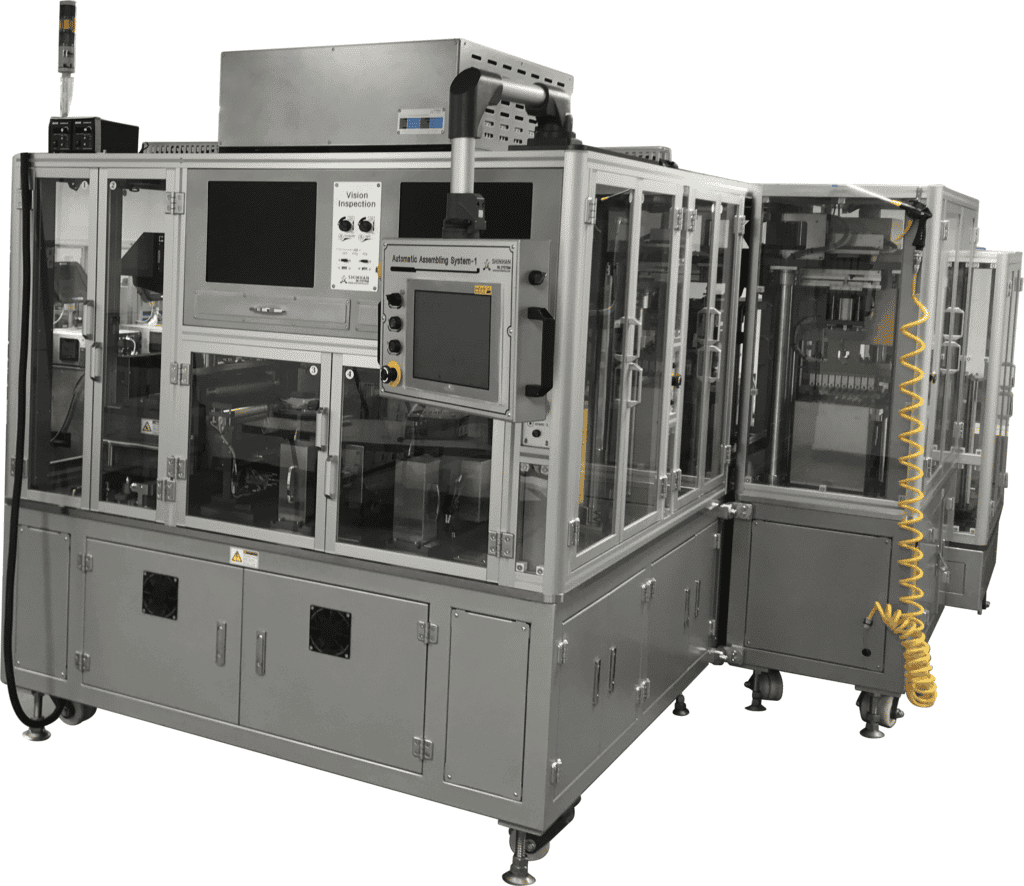

SHA-9000 10T Multi Assembly

PRODUCT OVERVIEW

The SHA-9000 Multi-Device Assembly system is for manufacturing the devices. It loads top and bottom devices onto the pitch transfer rail by gripper from the magazine and cuts the devices, transfers to index, 1st vision inspection on a card (membrane with laminated reagent), cut the card strip, assembles the cut strips (SCP unit) into the bottom case coupling top device with a bottom device, 2nd vision inspection, and release final products to discharging area automatically.

PRODUCT DETAILS

Main Features

- All operations include top feeding, bottom multi-device by 2 magazines, and SCP (Strip cut, pick and place) unit are done automatically.

- High productivity by SCP units and successive operation system

- Isolation of not fairly assembled device by 7 vision inspection units

- Easy operation by PLC touch screen

- Stable operation by applying servo motors

- Enhanced cost efficiency by minimizing labor input

Specification (Can be changed depending on applied devices)

- Model Name: SHA-9000 Multi-device Assembly System

- Applicable products: 10 multi rectangular shaped rapid diagnostic devices, uncut sheet

- Capacity: 9,000 EA per an hour

- Required manpower: 1 Person

- Bottom & Top Multi-device supply: 100 magazines

- SCP (Strip cut, cut and place) unit quantity: 1

- Isolation of incorrectly assembled product

- Main operation: by Servo Motors

- Strip cutting tool; Rotary Slitter

- Loadable card q’ty on a magazine: 80 Cards

- Power Supply: 3 Phase, AC 380 V, 50/60 Hz

- Control / Panel: PLC/Touch Screen

- Required air pressure: 5~7 Kgf/cm² (5~7 Bar)

- Dimension: Approx. 3,200 (W) x 2,500 (L) x 2,360 (H) mm

- Gross Weight: Approx. 3,900 Kg