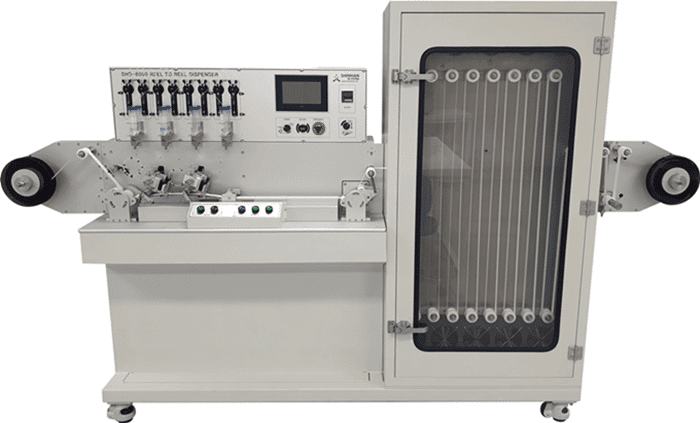

SHD-6000 Reel-To-Reel Dispensing and Drying System

PRODUCT OVERVIEW

SHD-6000 is an automated system machine that makes successive reel to reel supply of membrane, dispense a constant amount of reagent on the membrane, vision inspection, dry, and release automatically.

The system machine is suitable for a medium to a high volume reagent absorbed membrane production facility.

PRODUCT DETAILS

MAIN FEATURES

- High productivity with the least labor (1 person) input Efficient quality control by in-line vision inspection

- Stable quality production through keeping dry room temperature at a specific level

- Prevention of contamination that may occur by contact with a human hand in a manual production

- Easy setting (dispensing amount, speed, length, distance, etc.) and operation by Touch Screen

SPECIFICATIONS (Can be changed depending on applied devices)

- Model name: SHD-6000

- Needful number of operator: available from 1 person

- Dispensing method: Syringe pump

- Applicable product: Membrane roll

- Dispensing speed: 10~150 mm /sec.

- Dispensing amount: 0.2~10 μL /cm (Tubing Tip), 0.6~10 μL /cm (Sapphire Tip)

- Number of dispense line: 4 Lines (can be added by customer need)

- Accuracy(pump): +/-1% from target result at full stroke

- Precision(pump): Within 0.05% at full stroke (using 250 μl and above syringe)

- Dry room oven temperature: 30~60 ℃

- Control / Panel: PLC / Touch Screen

- System size: Approx. 3,000(L) x 700(W) x 1,800(H) mm

- Weight: Approx. 500 Kg

- Power supply: AC 110 / 220V, 50 / 60 Hz

- Required air pressure: 5~7 Kgf / cm2